Loctite Plastics Bonding System is a two-part cyanoacrylate adhesive that sets in seconds dries transparent and successfully bonds plastics with no mixing or clamping required. Component design knowledge.

Plastic And Elastomer Bonding Guide Henkel

It would be difficult to identify a manufacturing process which does not use plastics in one form or another.

. The trusted choice for professionals. The use of adhesives offers certain advantages over other binding techniques such as sewing mechanical fastenings or weldingThese include the ability to bind different. This video shows many adhesives available at TAP Plastics.

Can reverse engineer metal composite or plastic injection molded parts and can work with you to re-design re-engineer or re-produce those components. Overmolding is an injection molding process that allows an additional layer of resin to be. 2 The Loctite Design Guide for Bonding Plastics Volume 6 Plastics have become an integral part of everyday life.

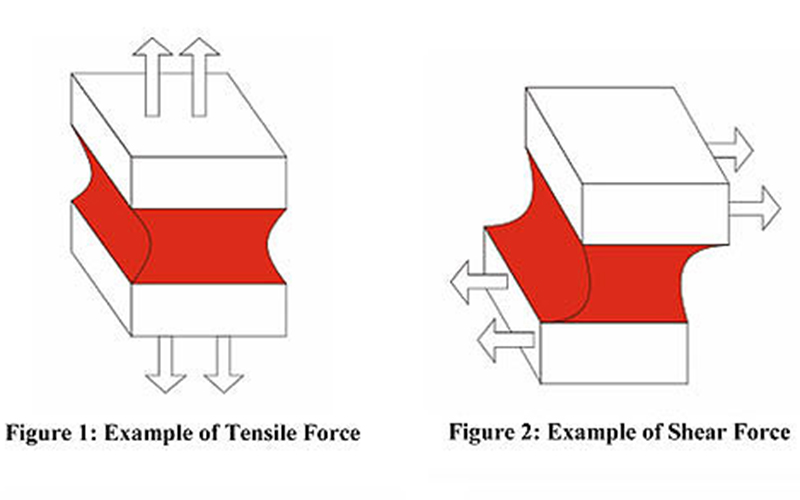

For starters while being easy to use and fast to apply they form bonds that are tremendously strong with some epoxies achieving tensile strengths of up to 5000 PSI. Values listed are typical and are meant only as a guide to aid in design. Creativity in molding process knowledge and material combinations.

It is intended to give the product designer the basic guideline to design a product that is of high quality and easy to manufacture plastic parts. 3Tek Globals mobile and stat. A A Magnetics Inc.

In Binder Jetting a binder is selectively deposited onto the powder bed bonding these areas together to form a solid part one layer at a time. Used in many characteristics products design and manufacturing of parts using thermoplastic components. Gasket design starts with compound hardness and profile selection.

The Role of Bonding. Field testing should be performed to find the actual values for your application. Engaging Read Mechanical Properties of Plastic Materials The Definitive Guide.

ABS Extruded Spec Sheet PDF. Overmolding and Insert Molding Design Guide A guide to two-material molding and bonding options with plastics elastomers and metal inserts. There are several custom design options we can apply to meet your.

Epoxy adhesives for bonding plastic are excellent solutions for many reasons. We manufacture a complete line of permanent magnetic assemblies including pulleys plates drum in housings grates and overhead. Compound development to meet specific application requirements.

API is experienced in molding all thermoplastics specializing in engineering high performance and glass reinforced resins. Plastics in both insert and two-shot molding processes. It is thus possible to shape and reshape these plastics by means of heat and pressure.

ABS can be adhered to itself and other like plastics using weld-on adhesives. When working with GLSyou get the benefit of a world-class application development team spanning. Provides a value to be compared withing different materials.

Additional Gasket Design Guide Considerations. A variety of plastic manufacturing processes have been developed to. Even products which appear to be composed exclusively of metals are usually coated sealed or adhesively joined.

Valuable tooling input. The design guide focuses primarily on Plastic part and Mold design. Plastics are the most common materials for producing end-use parts and products for everything from consumer products to medical devices.

Join composites to metal build with hard-to-bond plastics and use thinner lighter weight materials. This product can expose you to chemicals including Acrylonitrile CAS 107-13-1 which are known to the. Woodworkers builders and contractors depend on Titebond to deliver the most consistent highest-performing products to meet their demands.

Resistant to water most chemicals and even freezing temperatures Loctite Super Glue Plastics Bonding System delivers truly tremendous strength in just a single drop. One important advantage of this variety of plastics is that scrap obtained from old and warnout. At 3Tek Global we design create and support the Next line of mobile and stationary hammermill shredders and related downstream separation equipment.

Adhesive also known as glue cement mucilage or paste is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation. Culvert is constructed when the span of the structure is relatively smaller or the width of the channel is smaller. When there is no heavy equipment etc mostly it could be cast-in-situ concrete as lifting is required if we make it precast.

Yet engineers also need to consider part tolerances. Out of the above material list cast-in-situ or precast concrete culverts are more common. Plastics are a versatile category of materials with thousands of polymer options each with their own specific mechanical properties.

Adhesives bond and seal simultaneously eliminate stress. These plastics can be softened by heating and hardened by cooling any number of times without changing the properties of the material. The No Molds Required method allows us to design and fabricate your custom plastic enclosure without the need for expensive tooling or molds.

But how are plastic parts made. You can apply this adhesive. The greater the heat deflection higher the chances of a faster molding process in the injection molding method.

The materials commonly used in Binder Jetting are metals sand and ceramics. Improve product appearance with invisible joints and smoother bond lines reduce weight and noise enhance corrosion and fatigue resistance and more. In this guide we will discuss the best glue for acrylic and provide tips for gluing Plexiglass once you have gathered all your supplies.

Since they are constructed on the ground or. Buyers Guide How to Choose the Best Epoxy for Plastics. - 3M Fastbond is a water-based high-strength contact adhesive that offers excellent heat resistance and high coverage.

THERMO PLASTICS Thermo plastics. Both types of tapes come with peel-away release liners for ease-of-installation. Heat-activated taping system HATS products adhere well to the paints and plastics used with vehicles.

At Envision Plastics and Design we shape your ideas through our No Molds Required plastics fabrication technology. From strong plastics to polished metals Shapeways materials can bring your ideas to life. It includes chapters on the Plastic materials Part Design Considerations Design for Assembly and some topics on Painting Plating and Decorating.

4 Essential Techniques For Bonding Plastic Components Craftech Industries High Performance Plastics 518 828 5001

Loctite Plastics Bonding System

Loctite Plastics Bonding System

Structural Bonding Alternatives For Plastics Plastics Decorating

Structural Bonding Alternatives For Plastics Plastics Decorating

.jpg)

A Designers Guide On Development Of Advanced Medical Adhesives

Solutions Plastic Analysis Continuous Beams Structural Analysis Structural Analysis Mechanical Engineering Design Analysis

Loctite Plastics Bonding System Plastic Glue Super Glue Glue

0 komentar

Posting Komentar